VENTILATION

VENTILATION

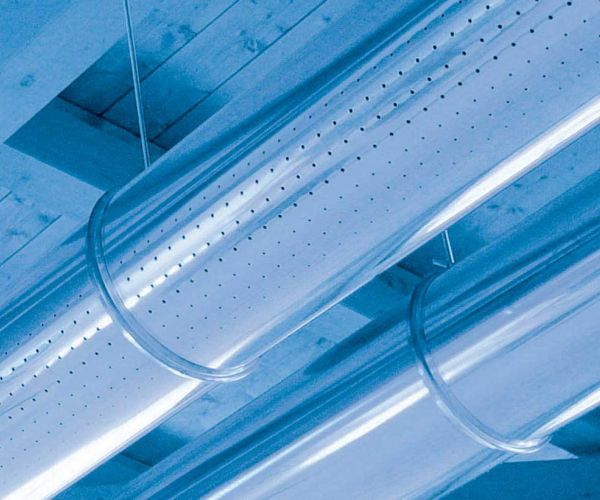

MICRO-FORATED TUBES

The CP Inox Micro-perforated ducts are a highly advanced and reliable solution for air diffusion mainly in commercial and industrial environments.

The advantages of a system made with micro-perforated channels are the following characteristics:

Customized design

Each system is designed according to the parameters required by the designer, the air speed, the outlet temperature and all the conditions are used and verified by the design program according to the current regulations UNI 10339 and EN 13182, verifying the operation real and nothing is left to chance, with attention to the fact that all parameters are respected especially at man height.

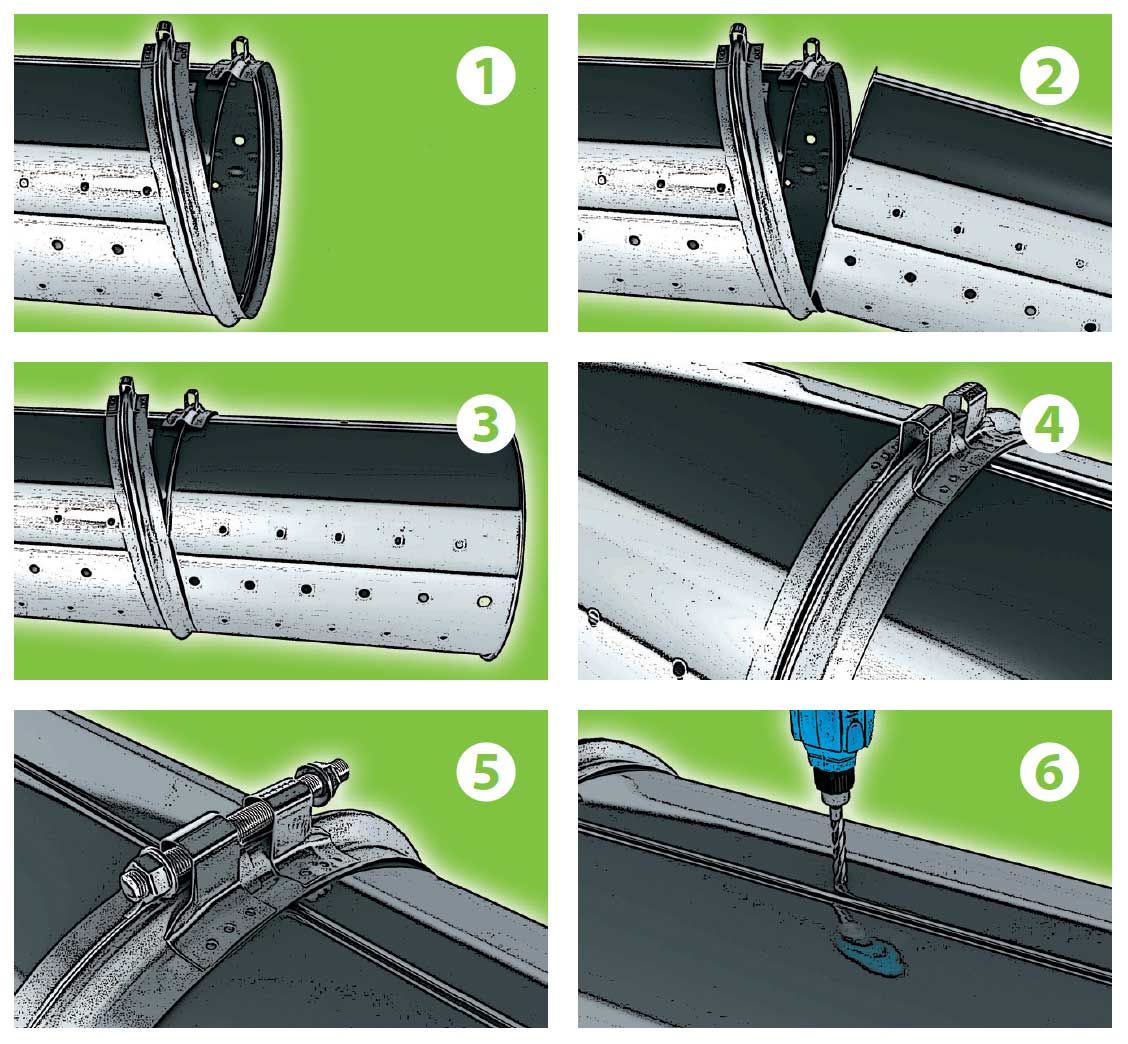

Ease of installation

The air diffusion system using micro-perforated channels, being sized and calculated by software, is accompanied by installation technical sheets, where each element is expressly numbered and assembly must be done in sequence. This feature makes it possible to considerably reduce errors and installation times and also allow the support structures to be optimized during the design phase.

Use of quality materials

The range of micro-perforated channels, produced by CP Inox, can be circular or semicircular in shape, to optimize the available space and can be made of both metallic and antibacterial materials. It is possible to make micro-perforated channels in stainless steel (304 or 316L) or galvanized steel or pre-painted sheet metal.

High thermal comfort

To ensure high thermal comfort, our engineers carry out the sizing with extremely advanced software, simulating in the design phase the final result and the quality of environmental comfort, both in summer cooling and winter heating. The parameters used allow a uniform distribution of the air, a homogeneous temperature, and also avoid the stratification of the ambient temperature.

High acoustic comfort

They exploit the concept of induction diffusion, thanks to calibrated and calculated air outlet holes, the air speed is always kept below the limits set by the legislation in any position of the environment, creating a high acoustic comfort.

Air quality

The use of noble materials, combined with the calculation of the ducts and precise diameters and position of the holes, avoids the formation of condensation and mold, as we are used to seeing with other air diffusion technologies

Versatility

The micro-perforated ducts are installed in commercial and industrial plants, in combination with air handling units and electronically controlled fans, they allow to optimize the regulation of the room temperature, both in working conditions at maximum power, but also in operating conditions partial power operation.

Pleasant and modern aesthetics

The use of pre-painted sheet metal according to the RAL scale, allows to integrate the air diffusion system with the adjacent structures and to optimize its aesthetics even in environments with a refined style such as restaurants, shopping centers, museums, halls meetings.

Indirect pollution reduction

The micro-perforated channels of CP Inox can be transported closed or open. If they are transported open, it is possible to close them directly on the installation site using the appropriate guide, optimizing transport with consequent fuel savings and reduction of atmospheric pollution.